Kicking off a business is tough, especially in a small town like Celina Texas. For the Celina custom shirt shops that exist or will exist, there are many pitfalls to look out for. Even the most versed in t shirt printing design can fall victim to these issues.Take a moment and read up on what you should avoid or take into account before you just through caution to the wind.

1. Being unaware of about screen meshes

One of the challenges a large number Celina custom shirt producers face is the idea that one size fits all with screen meshes. This is unquestionably not the case. You have got to take a look at how involved and in depth your artwork will be. In addition, the feel a user is seeking on the t-shirt. Even though your 110’s are superb for large, blocky artwork, they don’t handle the fine detail that a 230 can. Even so the 230 will not lie down the fullness of ink a 110 does. Nor will a 230 function as a easy underbase on a machine.

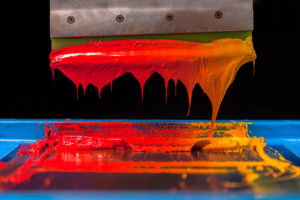

Are you printing “wet on wet” or flashing in between?

While printing wet on wet, you need to take into account each color not being overly thick so that you can stop the ink from bleeding. As well as how viscous your ink is normally. The likelihood of a blowout is more significant when you employ a runny ink and a mesh that is smaller count.

So do your research on different meshes

All these factors filter directly into selecting screen meshes for which colors. Do you consider that whenever a substantial Celina custom t shirt business receives an request that will need half toned, 4 color print which has an underbase that they make use of identical mesh throughout? No, certainly not. They decide on screens that can carry details without having to sacrifice productivity along with the vibrancy regarding colour. Do your research, conduct tests as well as take the time.

2. Not being totally sure just what inks you happen to be working with

Whenever a smaller store gets started out, several believe it is a smart idea to invest in a package deal of ink coming from a closing shop. This is frequently a major risk in each and every aspect. The shop you acquire this from could possibly have used particular brands as well as kinds of ink for his or her workflow. Subsequently you happen to be stuck using discontinued inks, custom made blends etc. Some being low cure yet others not, a few having bleed blockers. Several inks may have had fashion soft put in, and even out of date inks(and withouta doubt, they quite definitely do expire). This becomes a problem if you print for a recurring customer and have been using ink which has been discontinued. You sometimes need to discover it’s pantone equivalent in another manufacturer, or maybe blend it by yourself.

Inconsistency is the enemy

This usually results in a lot more factors that can be difficult to work out. Inconsistency isn’t acceptable when the customer may be depending on a standardized product or service to represent their organization. The perfect solution is not a hard one. Contact your neighborhood distributer and question them on whatever they suggest for the majority of your requests. It is preferred to be prepared for both 100% cotton and also 100% polyester. At the same time ensure that you question them the reason they will encourage particular products so that you will start to know what kind of ink is essential for certain fabrics.

3. Being either fearful regarding additives, or possibly far too generous using them

Additives can be a controversial thing in this particular industry. Several swear by these products while others outlaw all of them in the shop. But the truth is that they have unique functions and should never be applied away from these functions. Additives really should be put to use for a last option, seeing as to how they usually are heavy handed. Many can cause your ink to modify chemically and might end up in difficulties curing. As well can cause deficit of opacity, difference in expiration or simply causing the ink to lock up in the screen.

Being absolutely sure you need to use an additive is key

It’s for these reasons you will want to have a look at the amount of ink you might need and just how critical using an additive is. Mixing up a complete gallon with the additive might botch the full barrel, using up both time and money. Many times it is best to find and alternative to using an additive. By way of example: your current screen is just not clearing since the ink is simply not flowing through the screen. As an alternative to incorporating a soft hand, you can utilize a larger screen mesh. Or improve your squeegee angle. Perhaps even alter the print speed/pressure. In summary, know exactly what the additive does, know exactly how to use it, most importantly, WHENEVER and IF you should utilize an additive.

4. Not being aware of your customer

This mistake actually significant and frequently seen on a regular basis. Consistently be aware exactly who your current purchaser is. A Celina custom shirt printer would not likely to promote a really expensive tri-blend t-shirt to a Mom and Pops gardening company. These people would simply like their men to have basic t shirts to market and appear uniform, therefore a basic plain 100 % cotton is most ideal. On the other hand an ordinary 100 % cotton t-shirt could not be employed by a person hoping to begin a fashion series. To the same extent you must know fads and the standard is for printing.

Do not hesitate to alter your company’s product or service if need be

In the event that everybody is moving over to water-base, this might be an indicator to improve your print game. If the purchaser is disappointed with the way the print feels, possibly transitioning inks can be a important move. The consumer will be anticipating you to always be experienced in the industry as well as what is trending right this moment. You need to be the T shirts guru to your client. Oftentimes, your company’s common walk-in is not going to understand as much concerning t-shirts as you do, therefore understand the clothes you market regularly. It is recommended to have the ability to guide the buyer in the path they are really wishing to go. This way whenever they state “I would like my company t shirts to match this standard” you possess the proper clothes to match their standard.

Inquiries to ask your current buyer could be:

- What exactly are all these garments intended for?

- Exactly where will they end up being used?

- Do they require moisture wicking or no?

- Are you hoping to resell and/or these intended for additional purpose?

5. Improperly Spent Money

Numerous printers strive to cut corners and save a penny, which often, will go a long way within this business. However this could be problematic saving a penny effects your finalized product or service, as well as time frame it requires to create it. You might want to think about shelling out extra money beforehand to prevent long-term difficulties. You should not purchase out-of-date gear and systems when the industry has moved past it.

Be careful purchasing used equipment

If you want to purchase used, make certain it is both under warranty as well as in outstanding operating order. A lot of modest stores throw away an excessively high amount of time struggling with applications, re-adjusting machines, carrying out maintenance or even troubleshooting, and fixing misprints. Try not to be reluctant to invest in the areas that require top quality. For example: the way you generate positives for burning screens, the method that you burn screens and your press, etc. For your client, you are are generally the professional in Celina custom shirts. Ensure that your gear allows you to measure up to that.

6. Not enough Ingenuity and Imagination

You must not lose business when you are not able to resolve an issue. Understand what expertise you do and do not have. If you are not an designer, possibly employ one, or even look for a method to delegate to. May be the ink not curing? Contact the manufacturers of the ink and obtain the requirements. Let them help troubleshoot why you have the problem. A component of the equipment breaks? Do not close the shop. Get online find a method to obtain the component or a comparable part which will accommodate. Having the ability to resolve issues when they arrive is vital with screen printing. There is more often than not a simple solution. Each supplier of each and every component of your shop ought to be on speed dial.

Look to those who have been in the industry

Several have even developed a troubleshooting checklist or flow chart for each common issue. At the same time, any difficulty that happens at your shop has definitely happened at others, so check the t shirt printing design community forums. Even consider signing up for the Q&A internet pages to get all those resources for your use.